EV Batteries Are About to Get a Much-Needed Upgrade

Range really isn’t an issue for most electric cars anymore. But as with ICE cars, it’s not necessarily the size of the fuel tank, but how easy it is to get the fuel. With EVs, the problem isn’t battery size, but charging speed and battery longevity. Luckily, there are a few new developments that may solve some of these EV battery headaches.

Toyota’s solid-state EV batteries

One simple way around range anxiety is to make fast-charging stations (and home chargers) more prevalent. But that takes time and massive infrastructure investment. And even then, Battery University explains, lithium-ion batteries can only take so many rapid-charging cycles before they start to degrade. Toyota, though, may have a solution for this, Autoblog reports.

Li-ion batteries rely on a liquid electrolyte to carry ions and electrons in order to provide power. But this electrolyte, The Verge and NewAtlas explain, is flammable and potentially explosive, especially if the battery itself is old or damaged. It’s also corrosive if improperly cared for, the Handbook of Advanced Ceramics explains.

Toyota’s answer is to replace the liquid in electric car batteries with a solid, creating a solid-state battery. A solid-state EV battery, Automotive News explains, would be lighter and safer than a Li-ion one. It would also last longer and charge significantly faster. The recharge time for a vehicle like the Honda E could drop from 30 minutes to less than 15.

However, the solid-state design isn’t the only thing Toyota is investigating with its prototype electric car batteries. The Japanese automaker is also investing in a novel EV battery chemistry: lithium-sulfur. Li-S batteries are more energy-dense than Li-ion ones, and their materials cost less. They also avoid using an extremely problematic material: cobalt.

A few other EV and battery companies, though, are tackling that problem from a different angle.

Taking cobalt out of electric car batteries

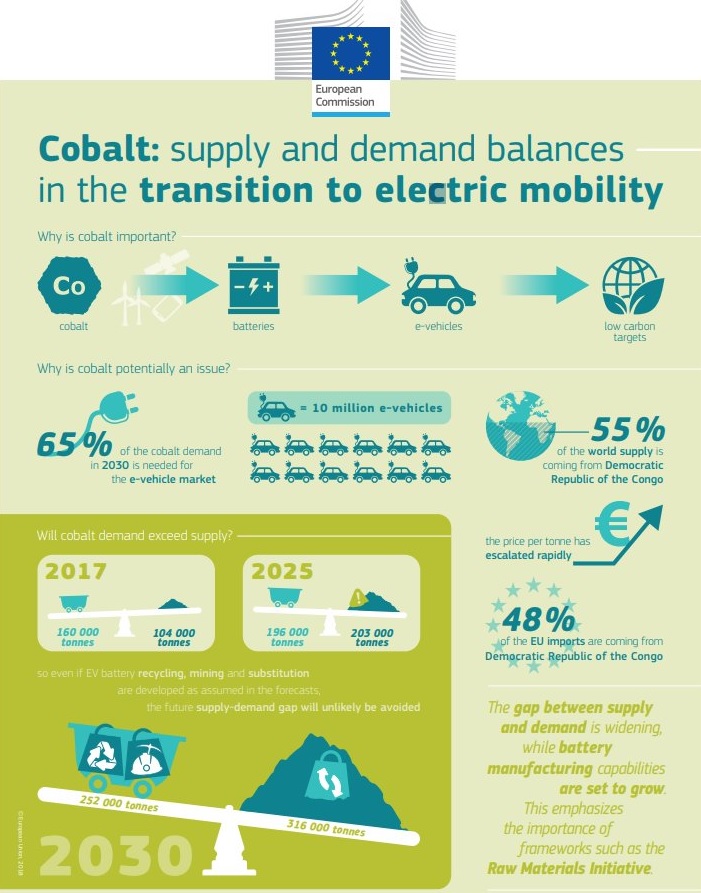

Although Li-ion batteries are built around lithium, they need cobalt and graphite for their electrodes, Chemical & Engineering News reports. Cobalt is the biggest factor behind EV battery prices, NBC reports, and demand is outstripping supply.

Worse still, a significant portion of the world’s cobalt is mined by horrifically-underpaid and overworked miners in the Democratic Republic of the Congo. And that includes children.

Many major battery suppliers have already phased out cobalt mined by child labor. Tesla and Panasonic, though, are taking it a step further, InsideEVs reports. Panasonic is Tesla’s primary battery supplier, and currently produces nickel-cobalt-aluminum EV batteries, TechCrunch reports. However, it claims to use less than 2% of the global cobalt supply in its batteries. It also claims that its batteries will be cobalt-free by 2023.

Tesla has also partnered with Chinese firm CATL, Reuters reports, to develop lithium iron phosphate batteries. LFP (‘F’ for ‘Fe,’ or iron) batteries aren’t quite as energy-dense as Li-ion ones, Epec Engineered Technologies reports. However, not only do they not use cobalt, they’re stabler and longer-lasting. But the new chemistry may not be strictly necessary.

InsideEVs reports several University of Texas at Austin scientists have developed a Li-ion electric car battery that doesn’t use cobalt. But it does use metals already found in Li-ion batteries: nickel, aluminum, and manganese. The new chemistry has no less in charging efficiency or durability, Green Car Congress reports. And according to the report published in Advanced Materials, it has “immediate synthesis scalability.”

How soon will these updates trickle down to consumers?

Cutting cobalt from EV batteries has another potential benefit: making EVs as cheap as ICE cars. According to Forbes, lowering an electric car battery’s cost to $100/kWh would virtually eliminate that price disparity.

As of this writing, the cost is about $147/kWh. Given that cobalt is 10%-30% of a Li-ion battery’s cost, Green Car Congress reports, eliminating it might drive that down to about $110-$120. However, LFP batteries could theoretically reach $100/kWh by 2024, Forbes reports, and $61/kWh by 2030. But that still requires getting a commercial version up and running. And the same goes for the University of Texas battery. Though in that case, the researchers behind it have already formed a company to commercialize it: TexPower.

So where does Toyota’s solid-state electric car battery fit in? At the moment, the automaker is working on overcoming Li-S batteries’ tendency to deform over time. Plus, making a Li-S EV battery requires a carefully-controlled ultra-low-moisture environment. The first working prototypes won’t be revealed until 2025 at the earliest. And even then, it will take a few years for the price to drop, because of the low production volume.

But all these developments are still stepping towards making EVs more affordable and attainable for all.

Follow more updates from MotorBiscuit on our Facebook page.