Supercapacitors May Revolutionize the Electric Truck, but Are They Ready for Production?

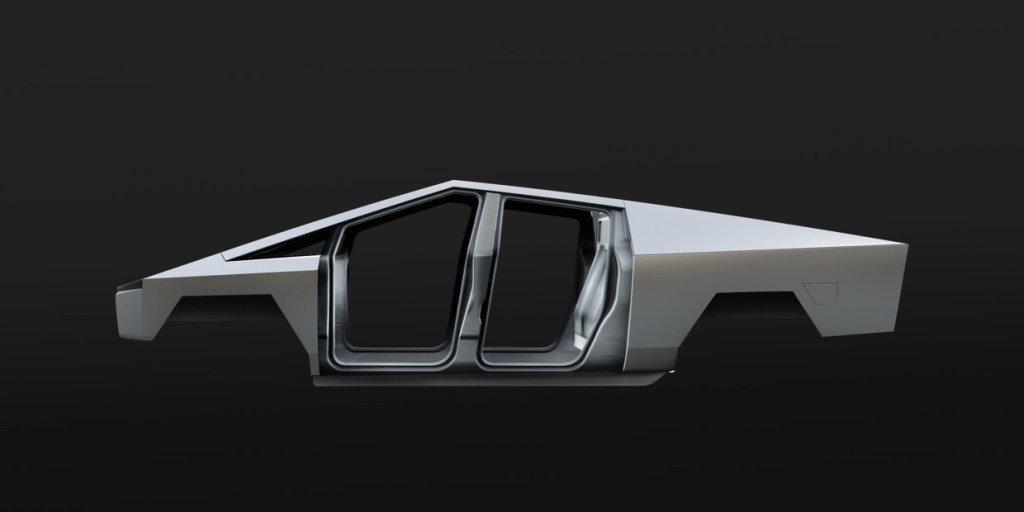

Electric pickup trucks like the Telsa Cybertruck, Bollinger B2, and Rivian R1T are just around the corner. But while they may be almost production-ready, potential buyers may hesitate over range and recharge time. Especially when towing gets involved. Hydrogen technology could help, but it comes with its own problems. However, there may be a different solution. And it comes courtesy of Lamborghini, an automaker which has no EV products. Nevertheless, its Sián hybrid supercar uses something that could be very beneficial to electric trucks: supercapacitors.

What is a supercapacitor?

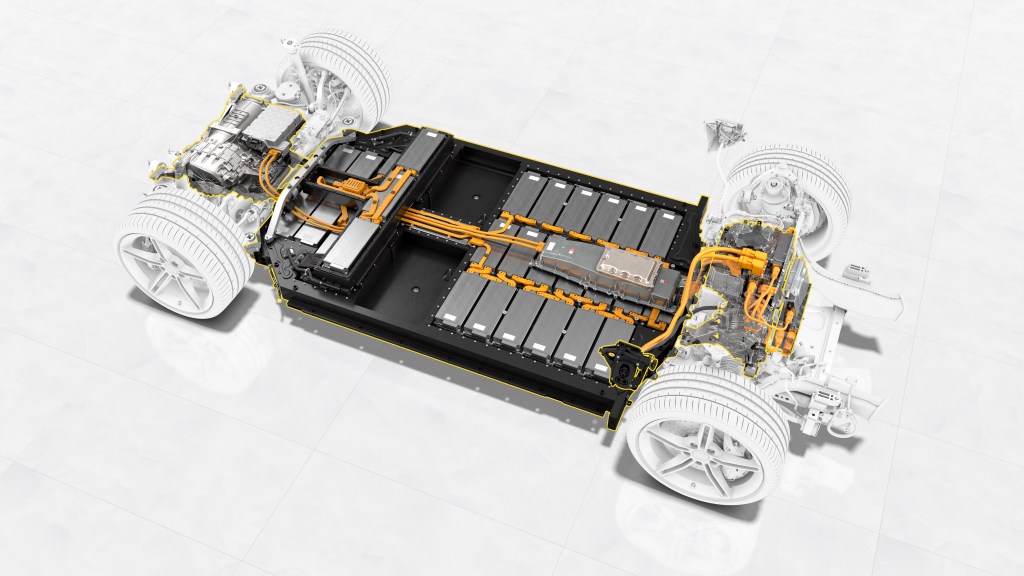

As Forbes and Car Magazine have described, capacitors are another way to store electricity. Unlike a lithium-ion or other battery, which has two electrodes separated by an electrolyte, capacitors are basically two plates separated by a dielectric, an insulating material.

In a battery, ions move through the electrolyte between electrodes, which is how the battery generates electricity. In a capacitor, however, positive charges build up on one plate, and negative charges on the other. Connecting the circuit then results in something like the static shock you get on a dry winter’s day when you touch a doorknob, only bigger.

Supercapacitors, aka ‘ultracapacitors’, as the ‘super’ and ‘ultra’ imply, are capacitors that can store significantly more energy, Battery University explains. They do this by having bigger plates, and less distance between them. The dielectric is also swapped out for thinner insulating material, and the plates soaked in electrolytes, adding even more potential energy.

Supercapacitors actually already exist in numerous electrical devices. For example, Samsung’s Galaxy Note 9 used supercapacitors to charge its stylus, according to The Verge. Supercapacitors are also already used in EVs, Car Magazine reports, in regenerative braking systems.

But supercapacitors may have more to offer for electric trucks and other EVs.

Why might they be good for electric trucks?

Supercapacitors are used in Lamborghini’s Sián and regenerative braking systems for two reasons: weight and recharge time.

In an interview with The Verge, Thomas Miller—a materials scientist with University College London’s Electrochemical Innovation Lab—stated that trying to power the Galaxy Note 9’s stylus with lithium-ion tech would’ve required a battery pack ‘the size of a Coke can.’ The Sián’s supercapacitor hybrid system weighs 75 pounds, as opposed to something like several hundred pounds for a battery pack. Supercapacitors also allow regen-braking systems to be relatively compact.

But it’s supercapacitor’s rechargeability that really sets them apart from lithium-ion batteries. For one, as Motor Authority described, supercapacitors have a 1:1 charge-to-discharge ratio: how much juice goes in is exactly how much juice comes out. That makes them more efficient than even the best batteries.

They can also recharge and discharge much faster than lithium-ion batteries. Porsche’s Taycan can fully recharge in roughly 60 minutes in the right conditions. Supercapacitors, meanwhile, can recharge in as little as a few seconds. Even a supercapacitor with enough capacity to power the Taycan could potentially take no longer to recharge than the average fuel stop. Which would mean towing with a Cybertruck would take no more time than towing with a gasoline or diesel pickup.

And because supercapacitors (mostly) rely on physical separation, not a chemical process, they last much longer than batteries. RideApart, reporting on Nawa Technologies’ EV motorcycle concept, states supercapacitors could potentially last through “millions” of charge-discharge cycles without “significant degradation.” The technology also uses fewer toxic materials.

Why are supercapacitors still so rare in the EV market?

Although supercapacitors do offer several important benefits over lithium-ion batteries, they have their share of drawbacks.

The biggest is energy density. Supercapacitors don’t have the same storage capacity as batteries. The Sián’s system, for example, can only contribute 34 hp. Making a supercapacitor system capable of powering an EV on its own would require the system to be bigger than the battery pack.

Supercapacitors also lose their charge faster than batteries. Park an EV in the garage for a week, and you might lose a few percent charge. Meanwhile, Forbes and Car Magazine claim parking the Sián for a few days would drain the supercapacitors completely.

The other issue, as is the case with any relatively-novel technology, is cost. Although capacitors aren’t new as a concept, using supercapacitors for vehicles is still fairly expensive. Not a problem for high-end vehicles like the Sián or B2, but not helpful for the every-day consumer. Especially not when it comes to making EVs more accessible for less-wealthy buyers.

Could they be practical for electric trucks?

At the moment, and most likely for the foreseeable future, a purely supercapacitor-powered electric truck is unlikely. But that doesn’t mean the technology is completely impractical or useless.

Lamborghini has begun tackling some of the energy density problems. In fact, the Italian automaker has partnered with MIT to develop ‘metal-organic frameworks’ to use as supercapacitor electrodes. These MOFs have large surface areas, which would automatically increase energy density. In fact, Lamborghini claims the MOFs could double storage capacity all on their own. But it will take some time for this kind of design to be fully production-ready.

The technology is being pursued in other EVs, too

But supercapacitors’ quick recharge/discharge nature is still extremely beneficial. Autoblog and RideApart report that French company NAWA Technologies call its Racer Concept motorcycle a ‘hybrid’ bike because it incorporates both lithium-ion batteries and ultracapacitors. Although supercapacitors have been used in regen systems before, NAWA claims this is the first instance where supercapacitors have been linked so closely to the ‘traditional’ battery-motor system.

The capacitors can quickly scavenge energy during braking and recharge the battery pack. And while the battery takes up to 80 minutes to recharge, the supercapacitors are full in 2. The nature of the ultracapacitors does means the bike, like the LiveWire and Zero’s bikes, is better for urban driving—186 city miles vs. 93 miles on a mixed cycle. But, linking supercapacitors this closely to batteries would be beneficial for electric trucks.

It’s possible this was why Tesla’s CEO Elon Musk reported an interest in ultracapacitors, The Verge reported. With the proper tuning, supercapacitors could be charged in-tandem with the battery, and provide boosts of power and energy when needed. Recharge times would be cut down, and performance possibly boosted.