Looming EV Battery Shortage Threatens Electric Car Sales

As automakers like Audi, Jaguar, and Porsche start to add electric cars to their lineups, some issues still remain. Most are centered around EV batteries, specifically their design and support. Current fast-charging infrastructure remains somewhat spotty, which forces companies to make larger and more expensive battery packs. And incidents like the Porsche Taycan fire aren’t helpful in trying to sell EVs to consumers, despite ICE vehicles also being susceptible to immolation. But there’s another EV battery problem on the horizon: material shortage.

Audi’s and Jaguar’s EV battery woes

Although Audi’s E-tron line is set to expand, Autoweek reports it may have to be delayed. According to Bloomberg, the German automaker is suspending production of the E-tron SUV temporarily. Its battery supplier, LG Chem, is experiencing production issues. This isn’t the first time Audi’s had to suspend E-tron production due to battery shortages, either, Autoweek reports.

LG Chem is also the battery supplier for Jaguar and its I-Pace SUV. And The Times reports that Jaguar, too, is having to suspend I-Pace production for the same reason. However, Automotive News Europe reports Mercedes is allegedly not facing the same problem with its upcoming EV crossover.

LG Chem’s problem isn’t due to the coronavirus, The Drive reports, although that has affected other automakers and other parts of the automotive industry. Instead, the issue comes from a lack of raw materials.

Why EV batteries have a bottleneck

Currently, EV batteries are based on lithium-ion chemistry. But, as the American Chemical Society explains in the video below, lithium isn’t the only element found in Li-ion batteries.

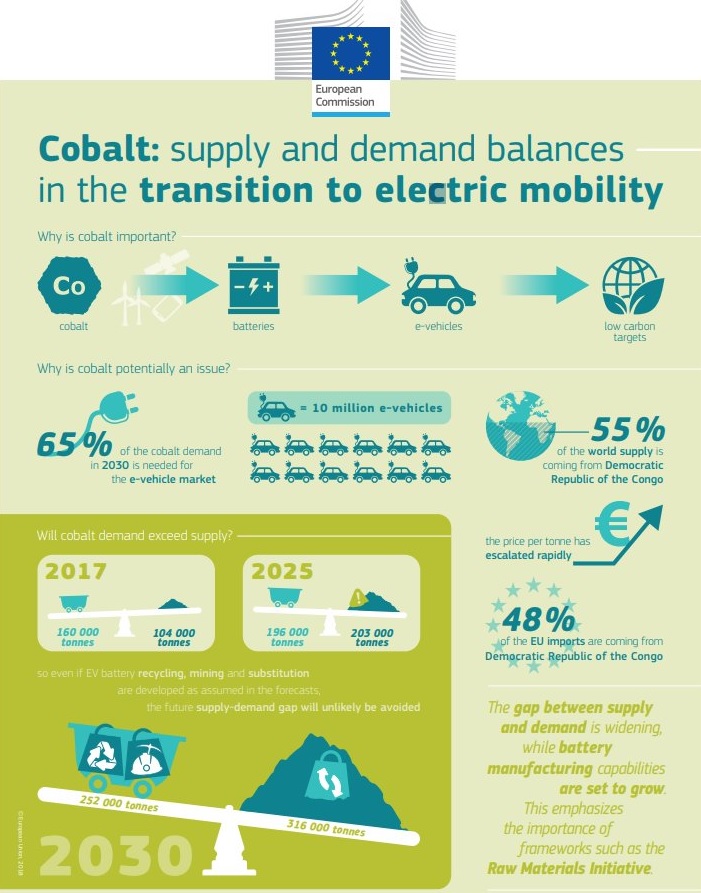

Li-ion batteries also require cobalt and graphite to make up their electrodes, although Chemical & Engineering News reports that other metal oxides, like nickel and manganese, are also used. When it comes to lithium, Wired reports we’ve actually got more than enough in supply. The problem is the cobalt.

According to C&EN and Battery University, cobalt is typically only produced as a by-product of nickel and copper mining. This means, as The Verge explains, if nickel and copper production drop, so does the cobalt supply. And Phys.org reports demand has already outstripped supply. And, while cobalt can be partially-substituted with the previously-mentioned nickel and manganese, it can’t be eliminated entirely from Li-ion batteries.

Which brings up the much more pressing problem with cobalt: the human toll.

The human cost of cobalt

As The Drive explains, over 50% of the world’s cobalt is found in the Democratic Republic of the Congo. And conditions there, as Forbes and the Washington Post have reported, are brutal.

Many of the mines there are hand-dug, and miners work 12-hour shifts for roughly $9/day. And often, the cobalt is mined by children. The situation brings back memories of the tantalum- and niobium-fueled ‘cellphone wars’ that rocked the nation in the 90s. Then, guerrilla groups were being funded through farmers scooping up ore instead of growing crops.

To be fair, WP reports that LG Chem stopped buying cobalt mined with child labor in late 2015. And although other companies, like Apple and Samsung, used an uncomfortable amount of child-mined cobalt in their products, Amnesty International reported, they are slowly eliminating it. Forbes reports that Apple has also started an education program for the child miners.

The problem is that demand for cobalt is already 9 times higher than the EU’s total production. Thus, Congo remains an important source for cobalt. And as demand for EV batteries grows, these issues have to be addressed immediately.

Potential solutions

There are, luckily, some potential solutions on the horizon.

For boosting recharge speeds, which would theoretically allow for smaller EV battery packs, supercapacitors are an option. They’re more efficient at storing energy than batteries and can discharge/recharge in a few seconds. At the moment, though, they’re too expensive and not energy-dense enough for full-scale EV production.

A more promising solution is an alternative battery chemistry like lithium-sulfur. Mercedes is currently using IBM’s quantum computer to attempt to mitigate some of Li-S’s flaws. Although a Li-S EV battery would be significantly more energy-dense, it degrades faster than Li-ion during discharge/recharge cycles.

There’s also the potential to eliminate batteries altogether, or at least supplement them, with hydrogen fuel cells. Nikola Motors already has several hydrogen EV semi-trucks on the road. Also, it’s currently planning on release the Badger, an EV pickup powered by a battery and a fuel cell. In the latter case, that also helps avoid the current problem with the hydrogen infrastructure.

Follow more updates from MotorBiscuit on our Facebook page.