Nissan Wants to Build Engines Completely Out of Carbon Fiber

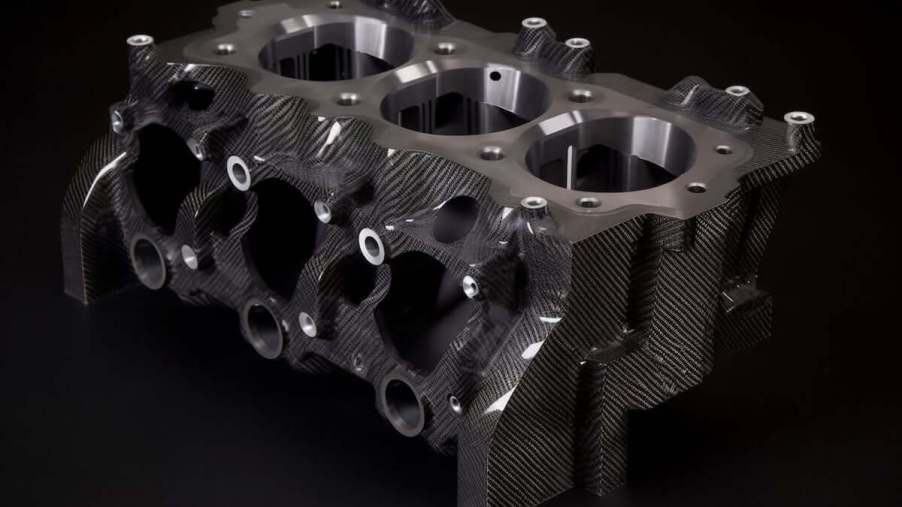

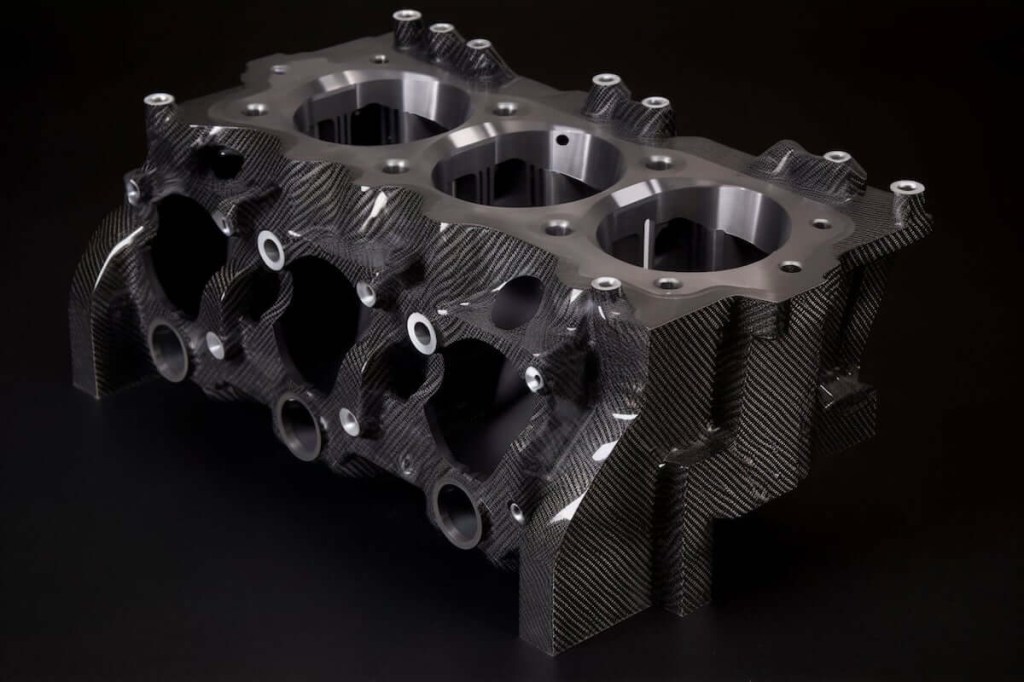

Carbon fiber is always held as better than steel because of its higher stress-resistant properties and lighter weight. It’s more expensive to manufacture, but in a mass-production setting, the prices come down. So it only makes sense that at some point carbon fiber will eventually be found in many products we normally associate as only being possible in steel. Like engine blocks, which is why Nissan just patented its carbon fiber engine.

Is the entire block made of carbon fiber?

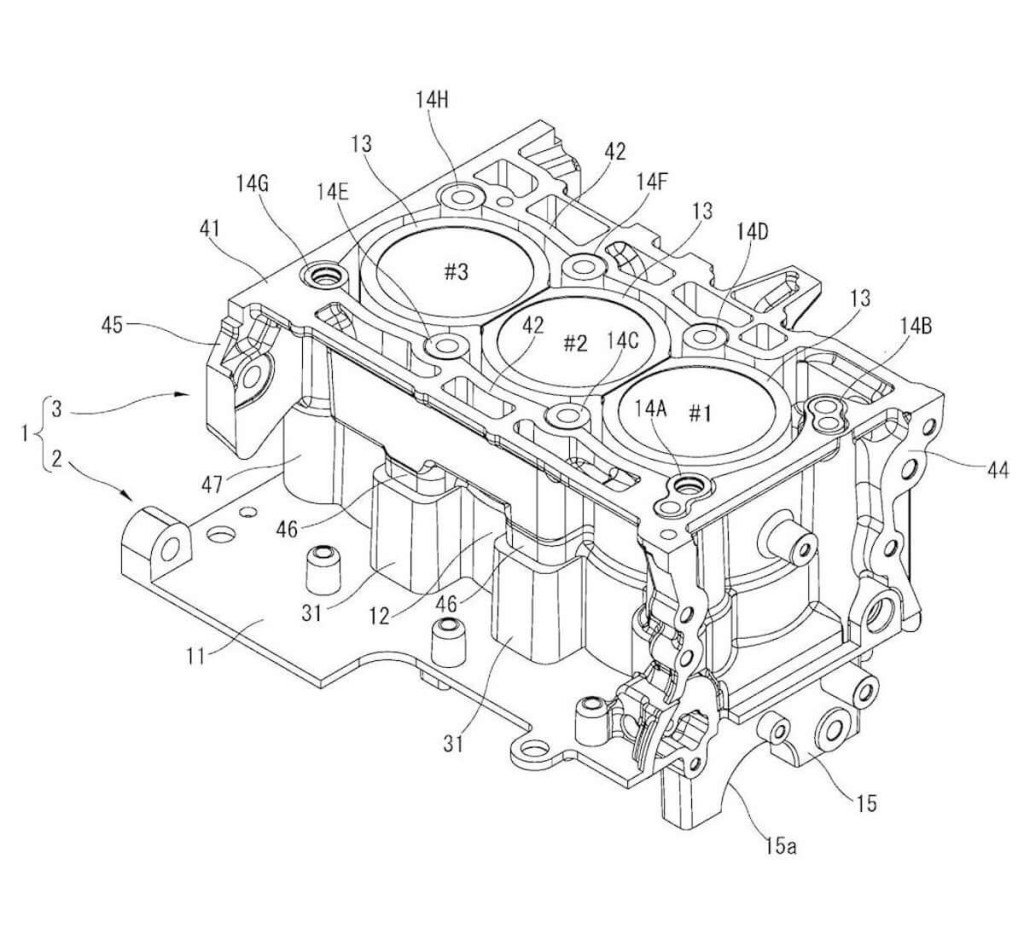

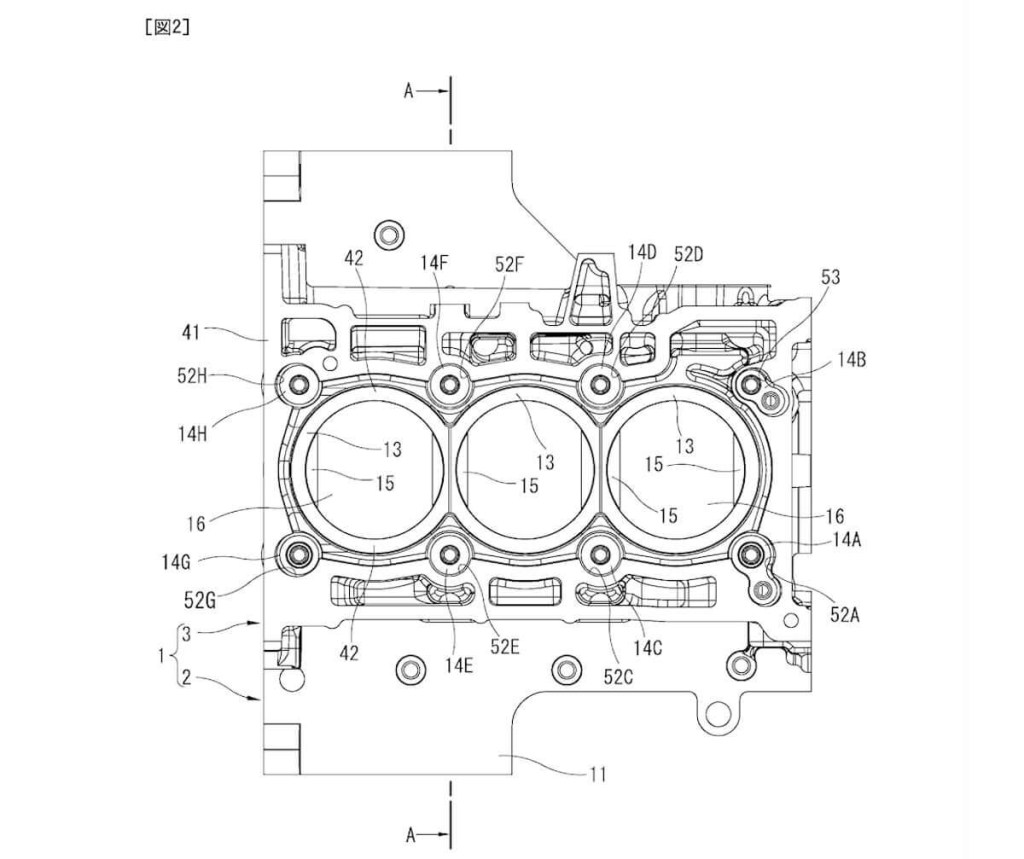

It’s not entirely carbon fiber. There are still steel cylinder liners, with the carbon fiber acting to hold them in place, so to speak. But it does make us wonder if an entire block might be entirely from the material someday.

How Nissan envisions this first stab at carbon fiber used for an engine is with a main block, which is the cylinders themselves. Carbuzz says the patent describes “A resin outer member which is welded to the main block.”. There are gaps between the main block and outer carbon fiber, which become water passages. It also helps to insulate the outer material from the heat generated in the cylinders.

That has always been the downside of the consideration of carbon fiber as an engine block material. Resins used in making carbon fiber can only withstand temperatures of around 250 degrees. Most engines never reach that temperature.

What are some of the downsides of a carbon fiber engine?

But thermal temperatures differ throughout an engine block. The carbon fiber matte can take a tremendous amount of heat, but not so the resin. This is especially true with piston friction on the cylinder walls. That is why Nissan has chosen metal liners.

And another problem with carbon fiber as engine block material is that oil, anti-freeze, and fuel could potentially attack the resin. Especially, oil can be a very aggressive chemical. Any of these could cause delamination of the matte.

Iron isn’t the only material for engine blocks. Engine blocks of aluminum, magnesium, and even titanium have all seen light. Of course, aluminum engine blocks have been around for years.

Magnesium, too, is a lightweight substitution for iron. But magnesium alloys don’t have the same strength as good old iron. But there are magnesium engines in production. Porsche used magnesium blocks from 1968 to 1977. But then, so has Ford, Mercedes-Benz, Jaguar, and even Kia.

Wouldn’t titanium make a better engine block?

As for titanium, yes, it would be a great substitute for iron, except for a few things. First, it is extremely expensive, so that pretty much kills mass production. But it is also difficult to machine. As there are different varieties and alloys for titanium, which pose different difficulties while machining. And exposing the weld to oxygen or nitrogen can cause severe embrittlement.

Nissan is well aware of the issues related to creating a carbon fiber engine block as we can see. One advantage it is looking at is that operating temperatures come up more quickly than with iron or aluminum. This should reduce the possibility of premature wear on certain surfaces.

But until further developments, both carbon fiber and also titanium are in a multitude of engine components like valves, piston connecting rods, and fasteners.