Report: Is GM Getting Its Electric Act Together?

A lot of what we hear out of GM lately is electric car-related. But when you look at the lineup of vehicles from GM there are few EVs. It has seemed like a bit of a puzzle. But now it looks like the EV picture for GM is becoming clearer. Its Ultium Drive system shows GM intends to hit the segment hard. Is GM getting its electric act together?

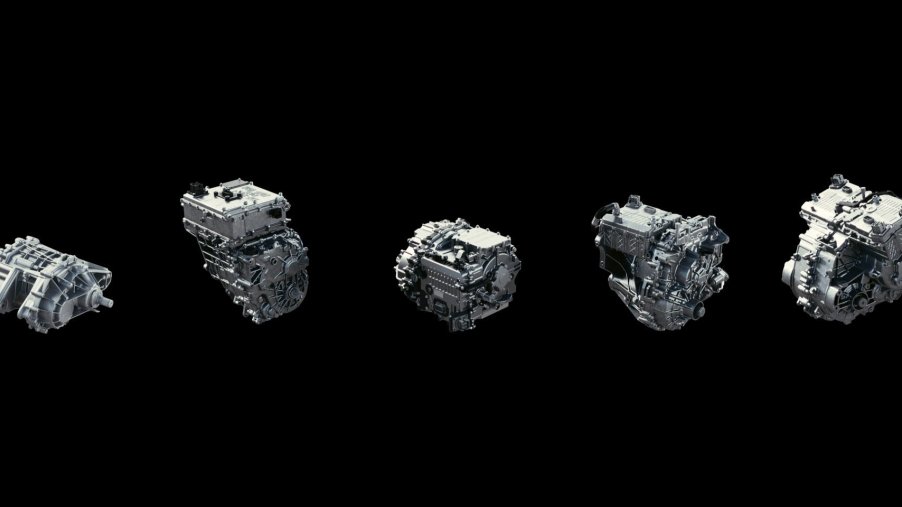

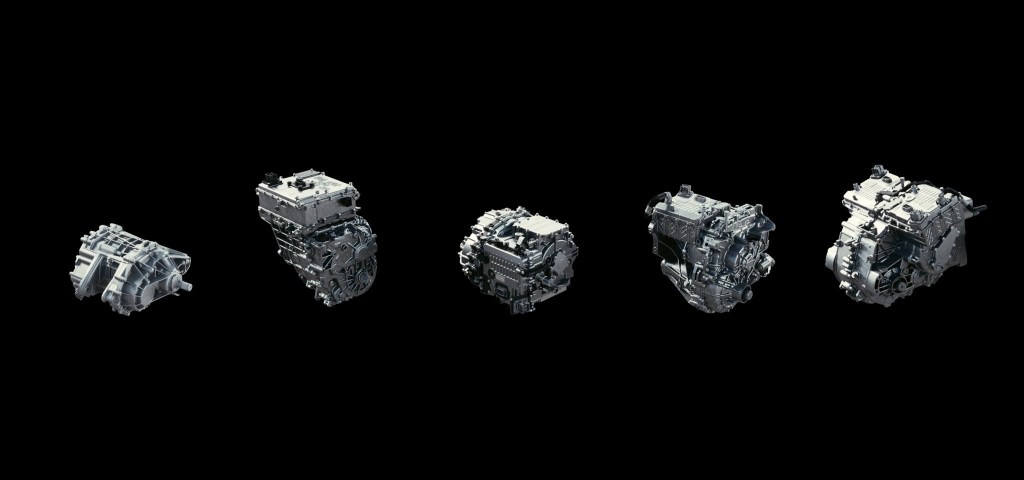

Ultium Drive is GM’s latest jump into electric vehicle technology. It is not one system but more like Legos. The combination of systems will work in a variety of packaging, sizes, and segments from small cars to trucks. Another advantage is that with this system GM can start cranking out many different models and combinations rapidly in large or small numbers.

GM wants to supply electric drive systems for themselves and other manufacturers

GM for years has made transmissions for manufacturers like Ferrari and Rolls Royce. So it is not a new position for them to look at supplying electric drive systems for themselves and other manufacturers. “Making motors, transmissions, driveline components, and systems are among GM’s best-known competencies, and our manufacturing expertise is proving not only transferable but advantageous as we make the transition to EVs,” says Ken Morris. He is GM vice president, Autonomous and Electric Vehicle Programs.

One of the big advantages of the Ultium system development is that integrating the electronics into the drive units has reduced mass by 50%. It also cuts costs and packaging space, yet it increases capability. The versatility is huge. Ultium can work as front-, rear-, and all-wheel-drive. It can be used as a high-performance or off-road besides variations in traditional vehicle segments.

Most EVs today use off the shelf components from outside suppliers

Most EVs today use off the shelf components from outside suppliers. In some ways, the company that uses those components are at the mercy of those companies. So it is unusual for GM to strike out on their own. Adam Kwiatkowski, GM executive chief engineer, Global Electrical Propulsion had an answer for Motor Illustrated about that. He said, “As with other propulsion systems that are complex, capital intensive, and contain a great deal of intellectual property, we’re always better off making them ourselves.

“GM’s full lineup of EVs should benefit from the simultaneous engineering of Ultium Drive. Our commitment to increased vertical integration is expected to bring additional cost efficiency to the performance equation.” One other huge advantage that has only been mentioned is that Ultium Drive components can be easily integrated into many existing GM component manufacturing plants. So ramping up to production will be easy to conduct.

Tesla should be very worried

Developing GM’s next wave of EV drive systems has taken a while, but the time, cost savings, and manufacturing integration, not to mention versatility, means it can hit the ground running. If we were Tesla we would be very worried.

While Tesla has made improvements on its vehicles over the years like the Model S, it looks like every other Model S. And it has been in production for almost 10 years looking the same. GM has the ability to add new models quickly and the capital to facelift models more often. How will that affect Tesla’s no-change strategy?