Pixelpaint is What the Future of Car Painting Looks Like

Painting cars today is about waste. A waste of materials, because almost one-third of them never get on the vehicle. For graphics and stripes, it is a waste of time because of having to tape them off. And both of those lead to a waste of money. But here’s what the future of car paint and painting looks like, and it is here now.

This paint process won the prestigious 2021 Robotics Award

Robots are mostly used by auto manufacturers, but these aren’t like those robots. These embrace the new technology just now entering into the painting process. And it even won a prestigious Robotics Award for 2021.

The award went to Pixelpaint, a process developed by a tech company in Switzerland called ABB. Though their process has been around for a couple of years it is only now being recognized for its groundbreaking techniques and results.

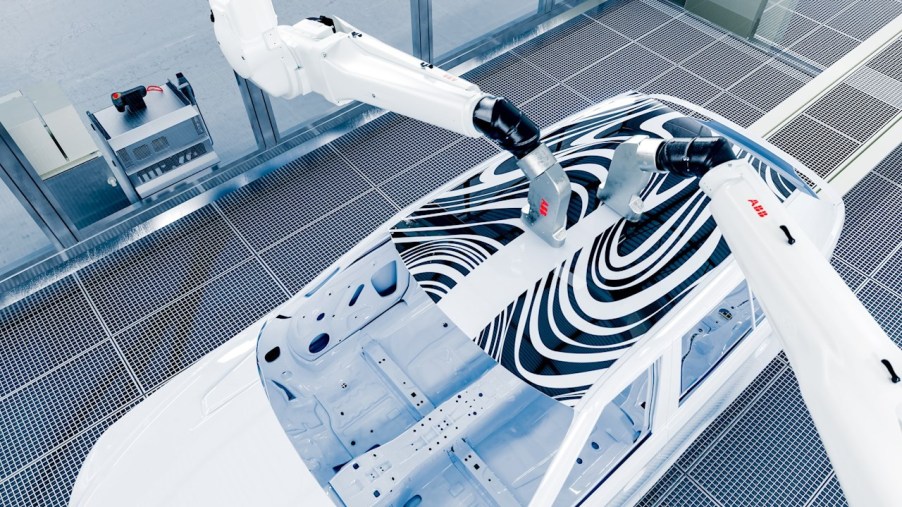

The process starts with two ABB IRB 5500 robots. They squirt the paint into a specified target area. But instead of using typical paint gun spray nozzles, it utilizes high DPI inkjet heads. These do a similar job to the inkjet heads on your printer, except these printing nozzles pinpoint the paint.

The Pixelpaint process sprays paint through a printing nozzle head

Spray painting has relied on a typical atomizer head forever. The Pixelpaint process eliminates that and instead sprays paint through a printing nozzle head. This method transfers 100 percent of the paint onto the vehicle surface. There is no waste.

Each print head contains over 1,000 nozzles that can be individually programmed. The nozzles don’t use the traditional flow jet process. Instead, they use droplets that can be controlled for size and how much material each droplet contains. So paint thickness and accuracy are increased.

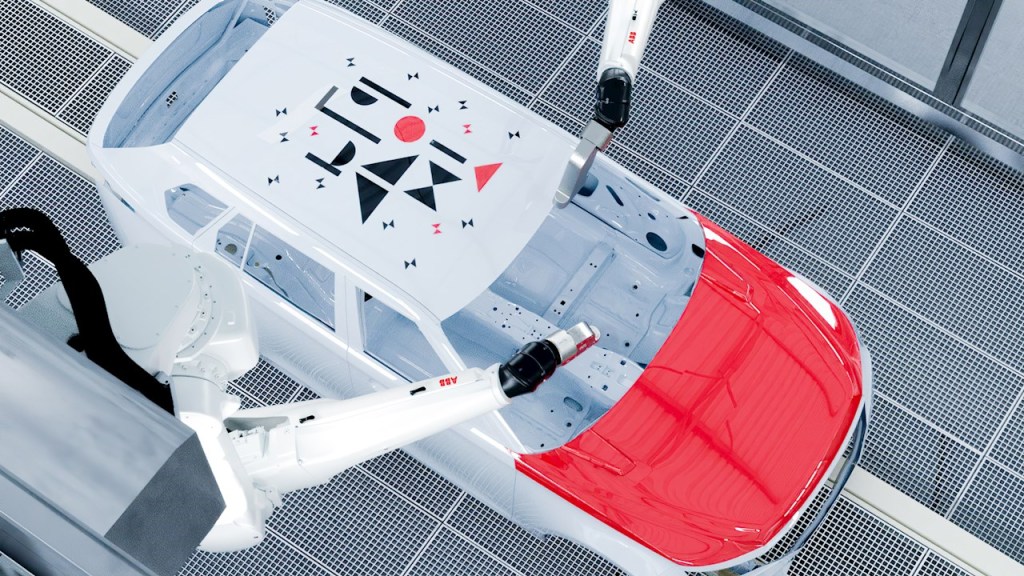

There is no more overspray, no more taping off windows, or for graphics on body surfaces. Program what you want it to create and it does the rest. Now all of the paint material is used with nothing going out into the environment. ABB says its Pixelpaint process is 50 percent faster than previous paint technology.

Custom paint and graphics use RobotStudio software

Masking off vehicles is no longer necessary. Now it can be handled through the RobotStudio software. Two-tones or graphics applications are greatly simplified. Highly individualized decorations are programmed right into the painting robots.

On an assembly line, every car can be painted differently from the next without line interruptions. The hand labor it used to take to lay down stripes or graphics is no more. Masking and then de-masking is unnecessary.

While it sounds like a perfect product for custom paint shops around the world, prices and availability are not indicated. So it is unknown whether the Pixelpaint process would find an application in individual mom and pop-type paint shops. But for manufacturing, the advantages are obvious.