How Carburetors Are Made

We may be witnessing the sunset of the internal combustion engine, but vintage muscle cars and other vintage vehicles are not going away anytime soon. There is too much “soul” and nostalgia tied to performance cars of the past. Enthusiasts cannot let them go, nor should they.

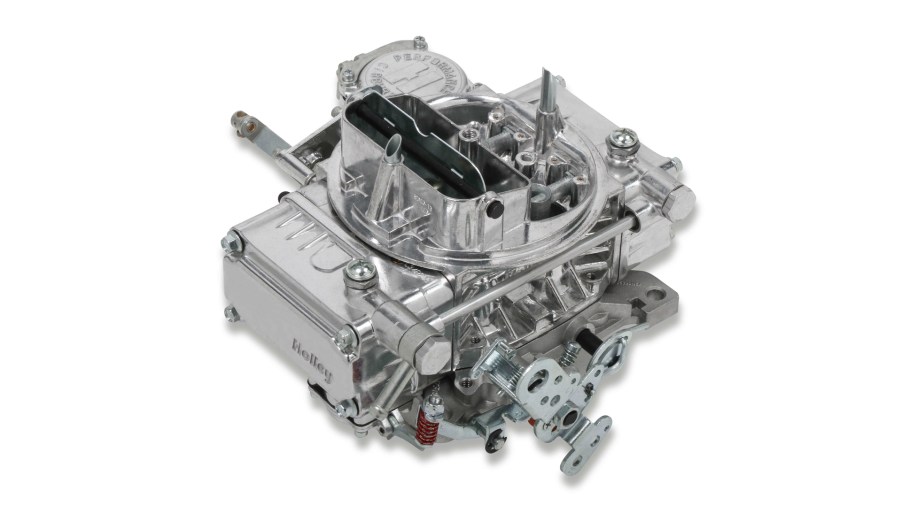

At the heart of every vintage muscle car is the carburetor. Before the age of computer-controlled fuel injection, carburetors controlled a car’s air/fuel ratio. Compared to fuel injection, people tend to look at carburetors as simplistic. In actuality, they are a very complex and nuanced device.

Destin from the YouTube channel Smarter Every Day became interested in how carburetor’s worked and created a video that simplified the process. However, he got a lot of negative feedback from his audience and was criticized for perhaps over-simplifying. So, Destin decided to visit the Holley Performance factory to learn more about how they are made and what makes them so impressive.

Carburetors have a ‘brain’

Traditionally, carburetors are not controlled by computers. However, that does not mean they do not have a brain. The primary function is to mix air and then send that mixture to the engine for detonation. In a vehicle equipped with fuel injection, the injectors are controlled with software that calculates the exact air/fuel ratio for optimal performance.

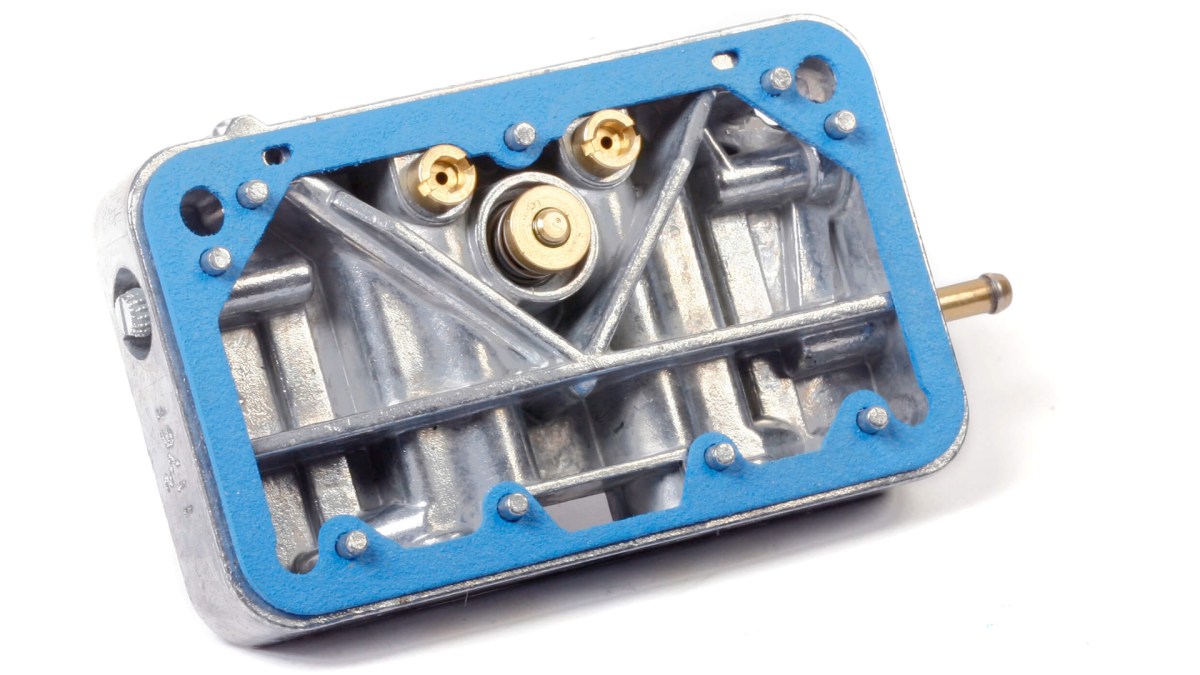

Carburetors use something called a “metering block” that performs the same process. Often referred to as the “brain” of the carburetor, the metering block features precisely machined pathways called “circuits.” Metering blocks have three circuits: an idle circuit, a transition circuit, and a wide-open throttle circuit used when the driver is going for maximum speed. These circuits are machined to exact tolerances to ensure that they function correctly, so they are cut with a CNC machine to guarantee accuracy.

A top-secret machine is used for testing

The amazing thing about carburetors is that they rely purely on precision machining to perform their functions correctly. Each carburetor’s groove, channel, and pathway serves a purpose and is connected to something else. As we previously mentioned, carburetors are quite complex.

Naturally, since there is no software involved in a carburetor’s main function, tests must be performed manually. Destin learned that Holley Performance has a special machine to test carburetors, but he had to blur it out in the video because the way the machine works is proprietary. Despite not being able to show it on camera, Destin learned that the machine can completely simulate the carburetor being attached to a running engine.

Watch carburetors get made from beginning to end

We have only provided a few highlights on the complete path of carburetor production. We would highly recommend checking out the full video to see and learn more. Granted, it is about 30 minutes long, so it is not a brief watch.

Though, we think that there is a lot to learn from Destin’s tour of the Holley Performance factory. Destin also loves to ask questions, so there is rarely a moment in the video when the viewers are not learning something.

We were pretty fascinated to learn that something most people think is simple is actually one of the greatest feats of engineering and is still evolving to this day.