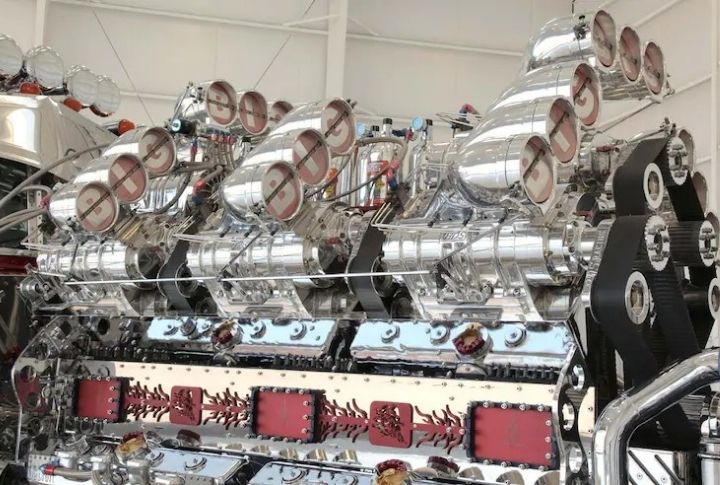

The Biggest Engine You Will Ever See In A Semi-Truck

The Thor 24 engine claims to have overcome all restrictions many smaller engines face. Its design looked impressive and promising, but many truckers are pessimistic. They believe the engine is impractical due to some unrealistic parameters. And there’s also the issue of its high cost. Here, we capture this engine’s distinctive features, highlighting its good sides and possible challenges.

What Makes It Stand Out

Numerous truckers appreciate the Thor 24 engine’s several positive aspects. The next few slides capture some of these qualities.

Massive Size, Power, and Torque

The Thor 24 semi-truck engine stands out in the industry with its 24-cylinder, 27-liter displacement that yields a staggering 3974 horsepower at 2500 rpm. Because of this, semi-trucks with this engine can effortlessly haul substantial loads. Also, the Thor 24’s torque performance enhances the vehicle’s towing capabilities and contributes to its overall efficiency and durability.

Advanced Fuel Injection

Thor’s highly intricate fuel injection system is built to handle the immense power generated by the massive engine, ensuring efficient fuel delivery to each of the 24 cylinders. Given the complexity and scale of Thor 24’s engine, the fuel injection setup is likely a highly customized, multi-point injection unit. It is engineered to optimize output and manage the precise fuel flow required to support the truck.

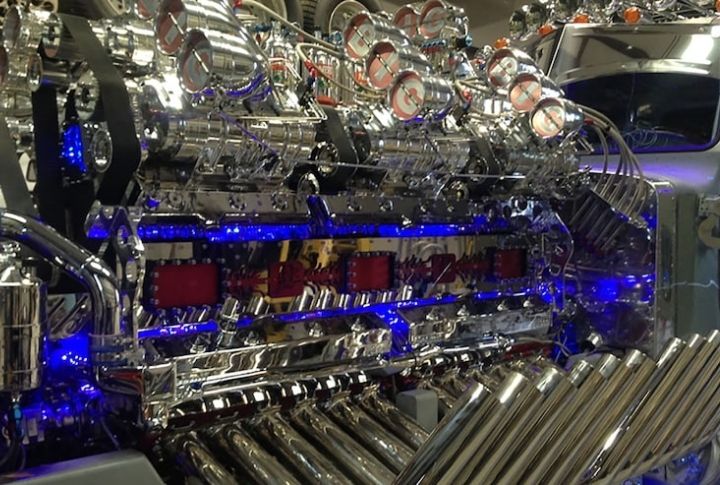

Sophisticated Cooling System

To manage the immense heat generated by this powerful engine, the Thor 24 employs a sophisticated cooling system, which includes oversized radiators and numerous cooling fans. Additionally, it has an advanced water pump to maintain a constant flow of coolant throughout the engine, preventing overheating. Such a cooling arrangement is essential to sustain the engine’s reliability.

Engine Block Materials

The Thor 24’s engine block is crafted primarily from cast iron, known for its strength and durability. This material will help the engine handle the immense power generated by its 24 cylinders. Some components may also incorporate high-grade aluminum alloys to enhance delivery and durability under extreme conditions. They will help the engine block to withstand the significant thermal and mechanical stresses imposed by the truck’s high-output engine.

Advanced Engine Management

Designed to optimize efficiency, Thor 24 uses complex algorithms and instantaneous data analysis to ensure optimal fuel combustion, engine timing, and power delivery. With its sophisticated control mechanisms, it adapts seamlessly to varying driving conditions, maximizing power output and fuel economy. Its integration of sensors, actuators, and electronic control units enables unparalleled responsiveness and reliability, making it a cornerstone of modern automotive engineering.

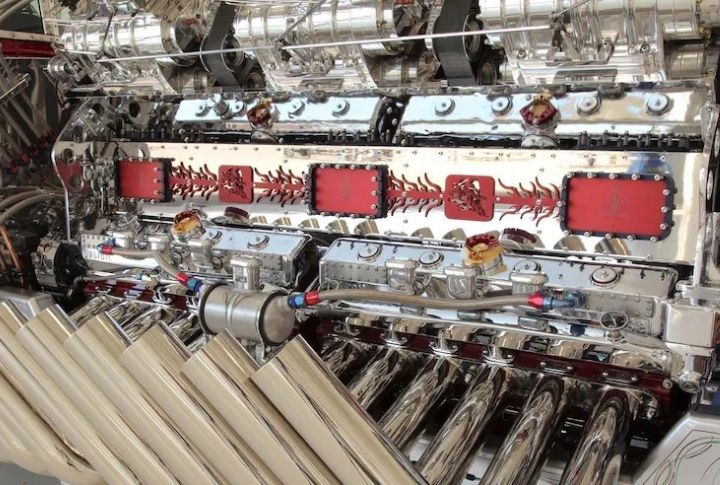

Enhanced Noise Reduction

Several sound-dampening materials are strategically placed around the engine’s key components to absorb sound waves and reduce noise pollution. Precision engineering further plays a crucial role by ensuring all engine parts fit together seamlessly, reducing vibrations and mechanical noise. This comprehensive noise reduction setup results in a quiet cab environment. It also reduces driver fatigue, leading to better concentration and overall safety on the road.

Challenges to Overcome

Despite these celebrated qualities, the Thor 24 engine has several drawbacks that limit its widespread use among freight operators. In the slides ahead, you can read about a few issues with the engine.

Emissions Compliance

Given its specifications and intended use, the Thor 24’s emissions are likely substantial. Such high-powered engines typically generate significant amounts of carbon dioxide (CO2), nitrogen oxides (NOx), and particulate matter, contributing to air pollution and environmental degradation. Unlike modern vehicles incorporating advanced emissions control technologies to minimize their ecological impact, the Thor 24’s design prioritizes raw power and spectacle, resulting in a much higher emission profile.

Limited Compatibility

Thor 24 Engine’s Monitoring System, boasting advanced features and functionalities, faces a challenge with compatibility when interfacing with older engine models or those manufactured by different companies. This limitation presents a barrier to widespread adoption across diverse vehicles and machinery, potentially restricting its utilization within the broader industry. As industries evolve and technologies advance, addressing these compatibility issues becomes vital to the system’s efficacy across different platforms and applications.

Costly Implementation

Implementing the Thor 24 engine necessitates a substantial financial commitment, which can pose a problem for small enterprises or individuals. Beyond the initial $13.2 million price tag for hardware and software, additional expenses may include training programs to ensure proficient utilization of its features. Such financial considerations impose strains on budgets, potentially dissuading prospective users from adopting the technology despite its potential benefits.

Complex Installation

Installing the engine is intricate and demands technical proficiency, particularly when seamlessly integrating it with preexisting systems. Its complexity poses potential challenges and can result in delays in deployment, hindering operational timelines. Furthermore, the intricacies involved often require specialized technicians, who may not always be readily available.

Maintenance Requirements

Akin to any cutting-edge monitoring system, Thor 24 engines require consistent maintenance to deliver peak performance. Regular repairs encompass calibration checks, sensor inspections, software updates, and system diagnostics. Due to its massive size, each service cycle takes much time, and neglecting it could jeopardize the engine’s dependability. Adhering to a structured servicing regimen safeguards against inaccuracies and mitigates the risk of unforeseen breakdowns.

Data Overload

The massive engine, known for its efficiency in data collection, inundates users with an overwhelming influx of information, creating a sea of data that can drown critical problems in the noise. Without sophisticated data analysis tools or adequately trained personnel, distilling actionable insights from this deluge becomes an arduous challenge, requiring a strategic approach and specialized expertise to navigate effectively.

Privacy Concerns

While the volume of information the powerhouse collects is invaluable for optimizing performance and ensuring maintenance efficiency, it also introduces privacy apprehensions. The potential for unauthorized access or accidental sharing of this data without adequate security safeguards is a considerable concern. Without stringent measures to protect this sensitive information, there’s a risk of compromising the privacy and confidentiality of individuals and businesses relying on Thor 24’s capabilities.

Training Requirements

Adequate training is essential for operators and repair staff to utilize the qualities of Thor 24 engines. Sufficient education ensures that users can accurately interpret data and effectively troubleshoot faults, thus maximizing their value. Without proper training, operators may struggle to navigate the complexities of Thor 24, leading to inefficiencies in data analysis and problem-solving. Additionally, maintenance staff need comprehensive training to ensure they can effectively maintain and repair the engine.

Risk of Technical Failures

While boasting advanced capabilities, the Thor 24 is not impervious to the risk of technical failures, which can manifest in various forms, such as hardware malfunctions, software bugs, or compatibility issues. Persistent hitches can disrupt operations, leading to downtime and eroding trust in the engine’s reliability. Implementing regular updates and ensuring prompt access to technical support is imperative to address these challenges.