What is Anti-lag and How Does it Work?

With any vehicle, adding a turbocharger means you will make more power and, in production cars, more efficiency. Most vehicles on the road these days have some turbocharging as a way to get the most out of a smaller engine. Manufacturers have used turbocharging since the early 1960s. With technology from automotive racing trickling down to production cars, advancements like anti-lag aren’t fit for the street. But what is anti-lag, and how does it work?

Why are all cars turbocharged now?

Turbo charging has become commonplace for auto manufacturers to get a balance between power and fuel efficiency. Using a smaller engine like a four-cylinder and a turbocharger, you can emulate the power of a bigger motor like a V8. Forcing colder dense air into the engine on acceleration enables it to burn more fuel. More air and fuel mean more power at the press of the gas pedal.

Turbo technology comes from developments in automotive racing. The money spent on manufacturing race cars is a way for companies to research new ways to improve road cars. Turbos did not become normal in production cars until the late 1980s. But the first production cars with them came from General Motors in the 60s, the 1962 Corvair and Oldsmobile F-85 Jetfire.

What is anti-lag?

Pushing the limits of turbocharging in racing, the first instance of anti-lag being used in proper racing was in 1981 with the Ferrari 126CK engine. The Formula 1 car is fitted with the twin-turbo V6 engine at the San Marino Grand Prix at Imola raceway. It provided a sharp exhaust note, spitting fire from the exhaust on deceleration, but had no wait time for the boost to kick in. This is because most turbochargers need to build up boost pressure before the power comes in, and falling out of that pressure range by letting up on the throttle will take time to build it up again.

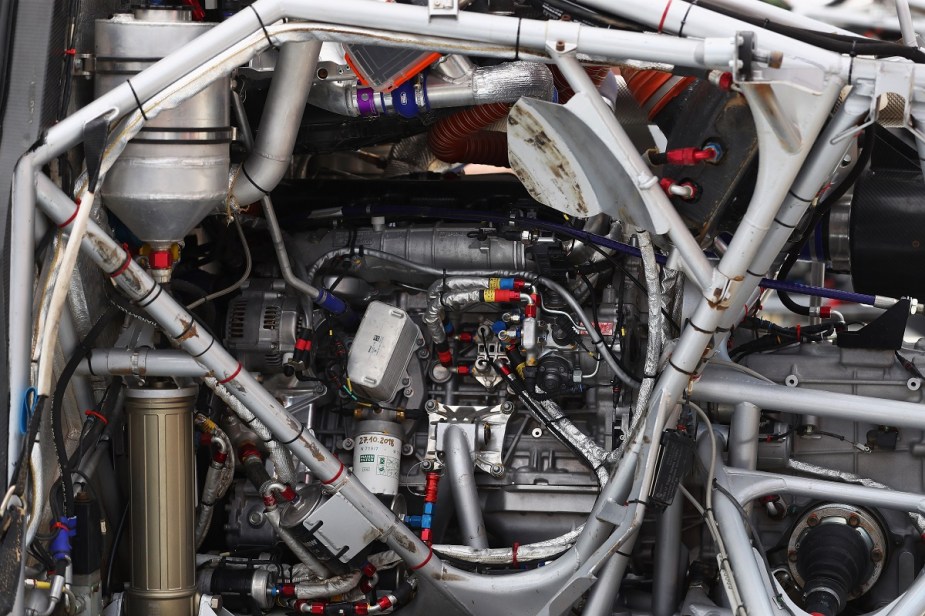

Anti-lag changes the power turbine into a gas turbine when the throttle is closed. A valve attached to each exhaust manifold runner will open on deceleration. The valve then diverts air around the engine (instead of going through it) into the exhaust manifold. The turbine housing speed is maintained by combining fuel, changed air paths, and ignition maps from the engine control unit (ECU). Once the throttle is open again, there is no build-up of the turbine speed, making the boost pressure essentially instantaneous.

Who uses anti-lag?

The technology is famous in rally racing, requiring instant boost pressure for accelerating out of corners. With an anti-lag valve in use, it shoots constant flames through the turbocharger to keep it spinning. If you watch rally racing, when they are slowing down towards a corner, you will hear a distinct noise from the exhaust. That noise is the anti-lag in use. One of the drawbacks of using anti-lag is that it will put more stress on the turbo, reducing the life span of the part. Since the technology reduces reliability and is inherently inefficient, you won’t find it on any road-going production vehicle.

Should you use anti-lag?

If you are building a rally racing car, anti-lag is extremely useful. You can buy an anti-lag valve from places like TurboSmart, making the technology available instead of reserved for race teams. However, installing the valve requires planning and the proper electronics to control it. For an average road car with a turbo, it is unnecessary and, in most cases, too expensive to make sense. But for some, it may be worth it for the noise alone.