Testing Electric Car Batteries Isn’t Quite Like Testing Engines

Before any vehicle goes on sale, it has to go through a battery of tests. Obviously, crash tests are a major part, as are emissions and range tests. But for performance enthusiasts, arguably the most important tests are for horsepower and torque. And for an electric Mustang drag racer to make 1400 hp or the Lotus Evija make 2000 hp, they need good batteries and motors. However, while an electric car’s batteries, like a combustion engine, make power, the two aren’t tested in exactly the same way. And, as with 0-60 times, test results and reality aren’t necessarily one and the same.

How a conventional engine gets tested

Performance isn’t the only thing engines are tested for, Car and Driver reports. Although engine designs can be flawed, each manufacturer runs its engines through numerous torture tests. Ford, for instance, runs its motors until their water temperature reaches 230° F, then shuts them off and pumps -22° F coolant through them. After 15 minutes, there’s a brief rest period, and then the test begins again. Test engineers repeat this process 5 more times.

For measuring engine output, though, the test procedure is a bit more standardized. The machine used is called a dynamometer, aka ‘dyno.’

There are 2 types: engine dyno and chassis dyno. Both work by having the engine work to rotate a resistive load, like a water wheel or large drum. An engine dyno connects the bare engine directly to the wheel. Meanwhile, a chassis dyno uses the fully-built car to spin a drum using its drive wheels. Based on how fast the load spins, the dyno computes how much power and torque the engine’s putting out.

Electric car batteries and motors, Hagerty reports, go through similar torture and performance testing. But there are a few key differences between the two.

How an electric car’s batteries get tested

For one, EVs don’t produce emissions. So, instead of emissions testing, electric cars have their ranges tested via standardized EPA procedures. However, just like ICE cars, electric car batteries are also subject to torture tests. Batteries work via chemical reactions, which are temperature-dependent. If it gets too cold or too hot, range and performance suffer.

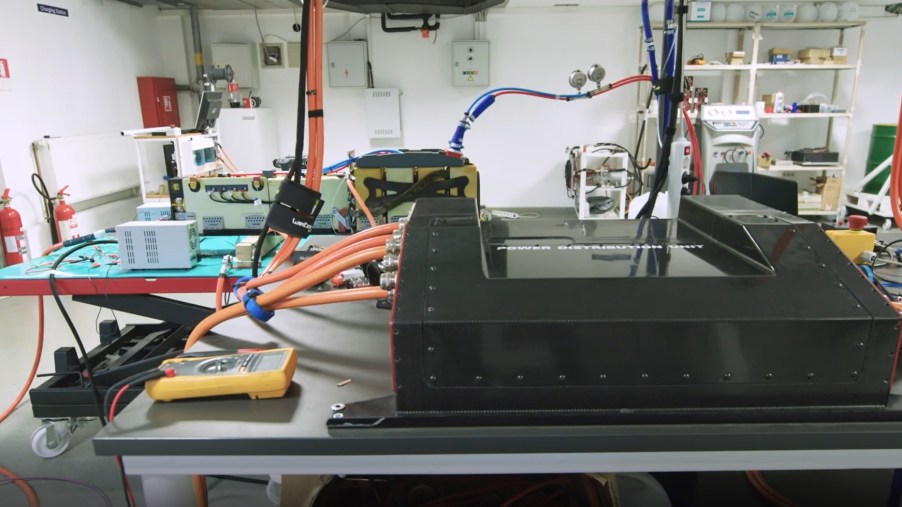

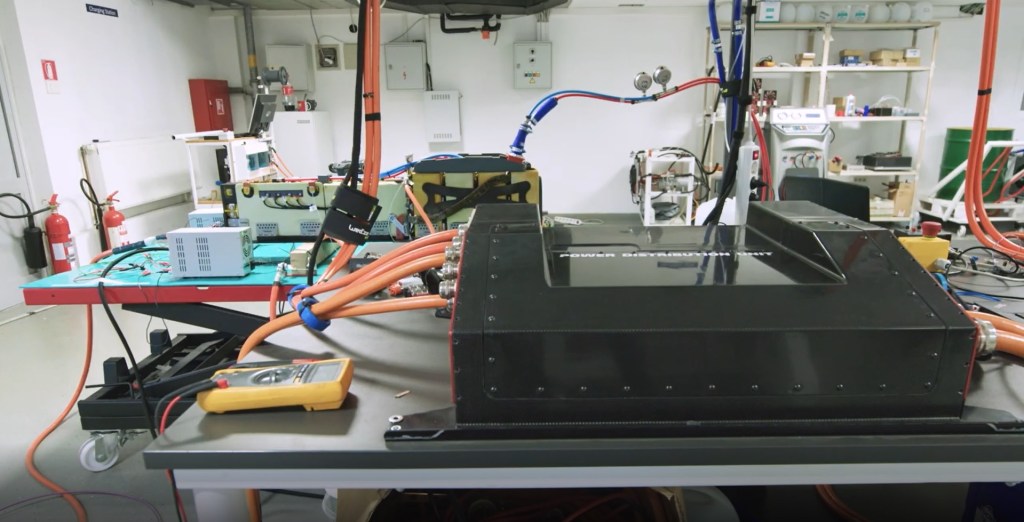

But, running an electric car’s powertrain on a dyno, as Croatian EV maker Rimac does, The Drive explains, is different from running a combustion engine. Firstly, there’s fairly little noise. To run a gas or diesel motor on a dyno, it needs to be revved up. The battery, though, just sits there. And even when the electric motor itself spins at 12,000 RPM, it’s not nearly as loud as a V8 would be.

Not only is there no noise, but the process can also actually be run 24/7. Basically, Rimac just charges up the batteries, then discharges them rapidly, to simulate full-acceleration runs. That discharged energy just goes straight back to the grid. There’s no fuel to add, no coolant to top up. No energy is spent operating a hydraulic brake or vented as waste heat. And the batteries can be tested for weeks straight with fairly little direct monitoring.

However, just like the EPA’s range tests don’t always reflect real-world range, a dynamometer isn’t a foolproof measurement tool.

Dynamometer results aren’t necessarily definitive

Using a chassis dyno over an engine one already introduces some uncertainty. That’s because the engine’s power has to through the transmission, differential, and through the wheels. That means there’s power loss. Usually, this is estimated at about 15%, but again, it leaves some wiggle room. But even an engine dyno can deliver wrong results.

In 2019, Motor Trend reported that the C8 Corvette produced significantly more than 495 hp and 470 lb-ft. However, it turns out the one at fault was MT, Jalopnik reports, not Chevrolet. MT’s dyno was set up incorrectly, missing a key parameter, and assuming the Corvette was all-wheel-drive. Because the dyno thought the Corvette was sending power through more wheels, it assumed the engine had to be making even more power, so the computer overestimated.

Engineering Explained’s Jason Fenske experienced something similar when he dyno-tested his Honda S2000. Over 4 tests, the dyno reported 4 different horsepower and torque figures. That’s because the technician altered how the machine was calibrated.

Follow more updates from MotorBiscuit on our Facebook page.