Major Car Manufacturers Horading Windshields for Looming Glass Shortage

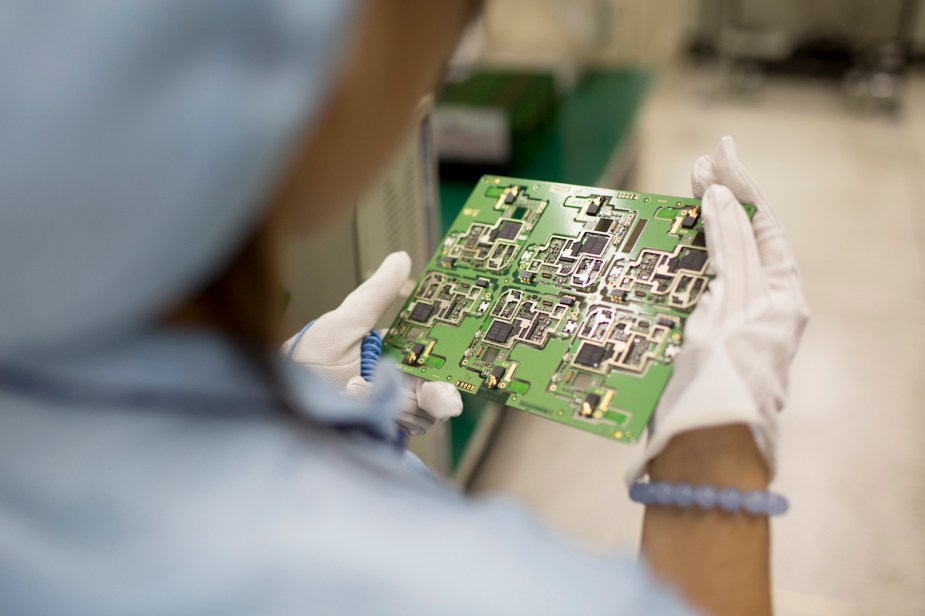

Volkswagen is hoarding windshields to prepare for a looming glass shortage. That’s right, the track never ends. Since the pandemic, we’ve been stuck in what feels like a never-ending log jamb of production issues, from the perfect storm that gave us the semiconductor chip shortage to the baby formula crisis. We keep revisiting the same issues. Now we are on to the next shortage; glass.

Is there a glass shortage?

The Wallstreet Journal reports that VW – the owner of many automotive brands – began stockpiling windows and windshields to prepare for an impending glass shortage in Europe.

As with many other issues in the world, this shortage in Europe stems from the unprovoked war in Ukraine at the hands of Russia. The war has driven gas prices to record highs in Europe and the States. This is now stretching into other industries that require fuel. Glass making, aside from shipping, requires enormous amounts of heat, which requires fuel.

The Drive mentions that the heat required in making glass needs to melt sand, soda ash, and limestone together, provided by natural gas. Although most media attention focuses on the price of diesel and gasoline, natural gas prices have also rocketed past the stratosphere.

This isn’t Volkswagen’s first supply chain issue of the year

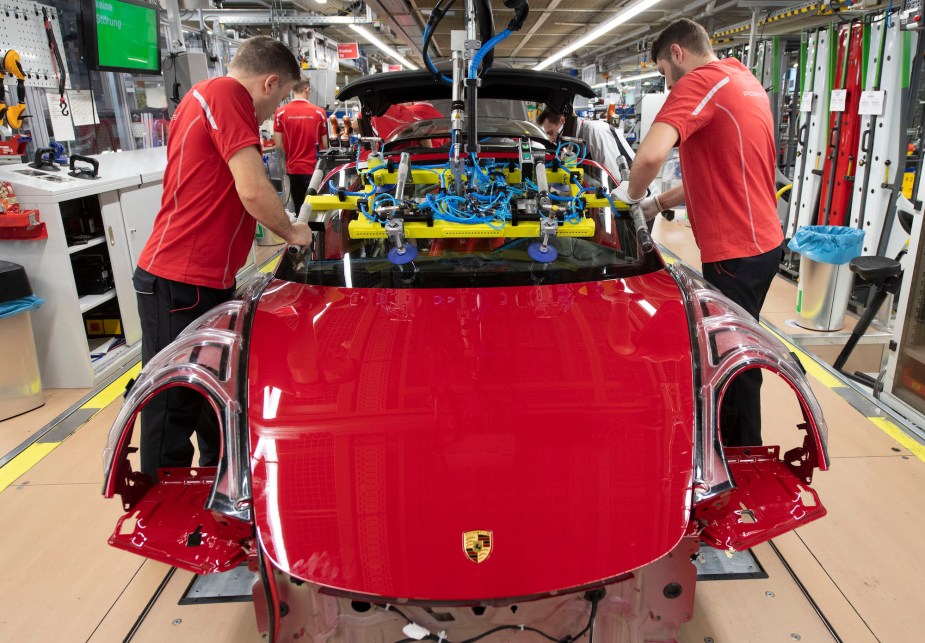

According to The Drive, Audi, Porsche, and VW, earlier this year, struggled to develop enough wiring harnesses to complete their cars because the parts came from Ukraine. All of these issues stemming from the war in Ukraine and the chip shortage caused automotive production to drop by 2 million units so far this year.

This glass shortage is only one part of the car manufacturing problem. Many other industries like food production, construction, technology, and more will also feel the shortage.

While stock-piling seems like something major manufacturers would do routinely, they really don’t. Stock-piling is actually very uncommon in today’s manufacturing best practices. Making just enough to fill the need is the chosen method, which tends to work fine when the world is not on fire. However, the last few years have been particularly tumultuous, begging the question: “should we change the way we do manufacturing to account for shortage prep?”

As a result of this practice, most factories don’t even have room for storage of materials, making the immediate fix even messier.

Have we learned our lesson yet?

If we haven’t, something tells me we are starting to. The shortages and factory closures have lost the world’s most wealthy corporations a lot of money. If history has taught us nothing, the mega-rich won’t suffer losing money for long. Between the war in Ukraine and COVID, manufacturers around the world are learning that supplies, materials, and employees on hand are where the money is.

Once VW at the bigshots at the top got a whiff of potential to lose more money, they snapped into action on the glass front. Preparing for any perceived shortage will likely become a major priority for all manufacturers.