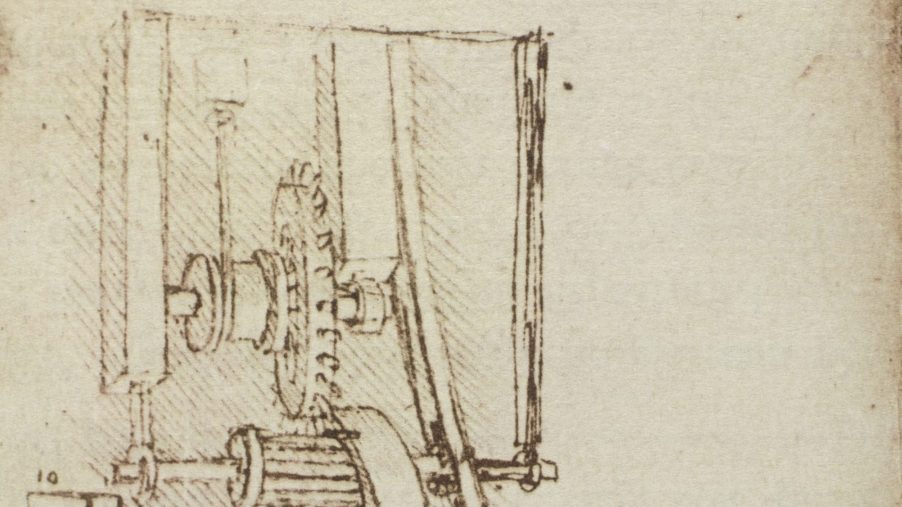

Leonardo di Vincci Invented the CVT Over 500 Years Ago

New technologies often make cars more efficient by using whatever latest breakthroughs we’ve had in the scientific world. The ability to shrink computer tech is probably the clearest example of this in the car world. We’ve seen space-age materials helping with weight reduction and safety, computer learning for self-driving cars, and sensors for lane assist and parking. But one of the newer trends, continuously variable transmission (CVT), isn’t really that new at all. CVTs were conceptualized nearly 500 years ago by Leonardo da Vincci (you know, the Ninja Turtle?).

Are CVTs really that old?

Come on now, y’all know the Ninja Turtles preferred skateboarding to driving. Of course, the inventor of the CVT was the Renaissance artist/inventor Leonardo da Vincci. And, yes, he drew out ideas for the continuously variable transmission all that time ago, according to the folks at How Stuff Works.

I guess the CVT isn’t necessarily new tech. Outside of the original Leo D. first sketching it out, Car and Driver lays out a series of automakers that built and used CVTs from as early as 1910.

Zenith Motorcycles a CVT in one of their motorcycles in 1910. It was seen as being too efficient to be allowed to compete in hill climb events. Other manufactures like Subaru tried again to incorporate CVTs in the early 1980s. but only recently has the CVT become a household name.

So, it really isn’t new at all, but it hasn’t been widely used until pretty recently. So what exactly is it? How is it different from a normal automatic transmission? And, is it better?

What exactly is a CVT?

Let’s start with the basics of a transmission. A very simplified explanation of transmissions is basically a system that allows a vehicle to switch between a number of different gears to effectively use the power of the engine to traverse different drivings conditions like acceleration, top speed, and climbing hills. Manual transmissions allow the driver to choose which gear they want in any given scenario while automatic transmissions choose for the driver based on the output needed from the motor. So, where do CVTs fit in?

While CVTs are automatic, they are built using a system of pulleys to manage the torque as opposed to the literal gears ( interlocking toothed wheels) in normal automatic transmissions. Trading the gears for the pulley system eliminates the “gear shift” by creating infinite variability between the highest and lowest gears, as explained by How Stuff Works. It is important to note that although CVTs don’t have literal gears like a regular transmission, it still uses the same terminology to adhere to convention.

K.I.S.S.

Most CVTs only have three basic components: A high-power metal or rubber belt, a variable-input “driving” pulley, and An output “driven” pulley. How Stuff Works explains it like this, “The variable-diameter pulleys are the heart of a CVT. Each pulley is made of two 20-degree cones facing each other. A belt rides in the groove between the two cones. V-belts are preferred if the belt is made of rubber.”

Basically, there have to be two pulleys, one attached to the crankshaft and one attached to the driveshaft. They are continually adjusting to one another, making the “gear changes” so seamless and smooth.

The CVT is taking the complexities and physical wear and tear out of the transmission game. With conventional transmissions, there is metal on metal friction, brakes, clutches, and a slew of other complications that can make maintenance and reliability an issue.

The CVT’s success comes from its simplicity. The belts and pulleys are much simpler and less aggressive than their teethed counterparts. Not only are they more straightforward, but they are much smoother shifting transmission and offer infinite gear ratios and can squeeze the most power out of a smaller engine.

What took them so long?

If CVTs have been around for so long, then why are automakers just now using them in earnest? They are more efficient for fuel and power, simpler to work on, and easier to maintain. What are we missing? Car and Driver explains that with the call for smaller, more fuel-efficient motors, CVTs are simply more efficient. CVTs get more power out of a smaller motor as well as better fuel efficiency. The full adoption of automatic transmissions being seen as standard makes the need for more efficient and smoother transmissions all the more valuable.

We have come unquestionably far with automotive technology, but even after 500 years, it seems we still haven’t beaten good ol’ Leo D on transmissions.