The Insane, Hard-to-Pronounce Technology Behind the Koenigsegg Jesko

Christian von Koenigsegg is a genius. Now, his hypercar firm has applied that genius to the Koenigsegg Jesko, the brand’s ultra track-focused hypercar. And it’s not just the Jesko. Recently, the brand has made leaps and bounds in both sustainability and performance that it has applied to a range of models, from the Jesko to the Regera, to the Gemera. In many ways, a tiny factory in Angelholm, Sweden is pushing the envelope more than a litany of larger, better-funded brands.

The Koenigsegg Jesko’s Lightspeed Transmission is insane

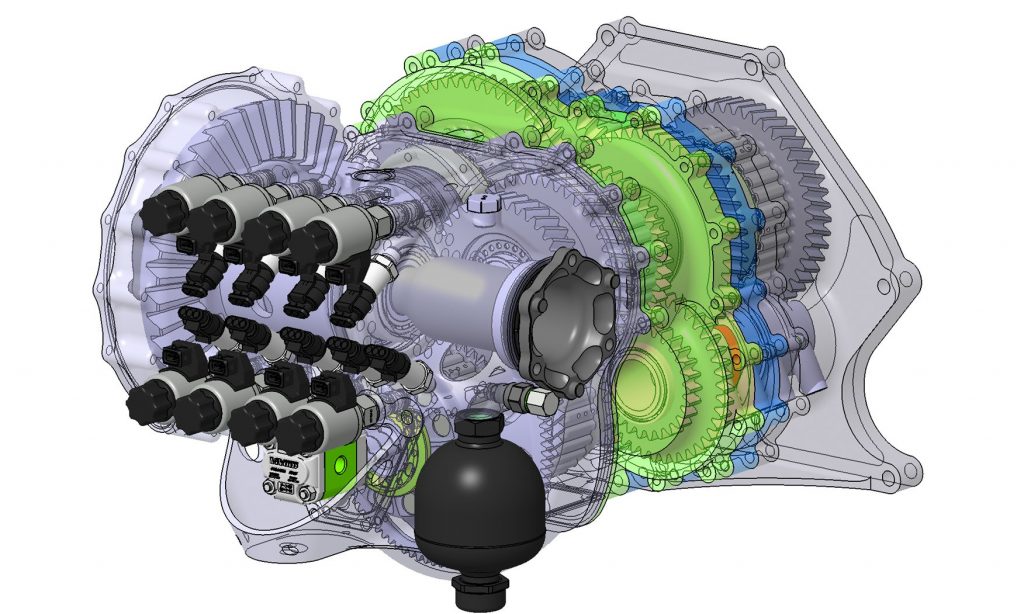

Let’s start with one of the most universally used aspects of any car: the transmission. It’s an old principle that functions just like that bike your kids don’t ride. A shaft moves gears, creating different ratios, propelling a vehicle forward. However, founder Christian von Koenigsegg sought to fix something that wasn’t broken. Koenigsegg (the company, not the cheerful Swede) call it the Lightspeed Transmission (LST).

Usually, a standard automatic transmission uses one, maybe two clutches to mate the gears to the motor. Clearly, Christian von Koenigsegg thought this wasn’t enough. The LST uses seven multidisk clutches to move through the gears. Moreover, the company pioneered predictive software that pre-selects gears for you, virtually eliminating shift times. Basically, should you be rich enough to be in the driver’s seat, you’ll never feel the transmission make a gear change. All that is done in “virtually zero time” according to Koenigsegg.

Koenigsegg continues to push the envelope

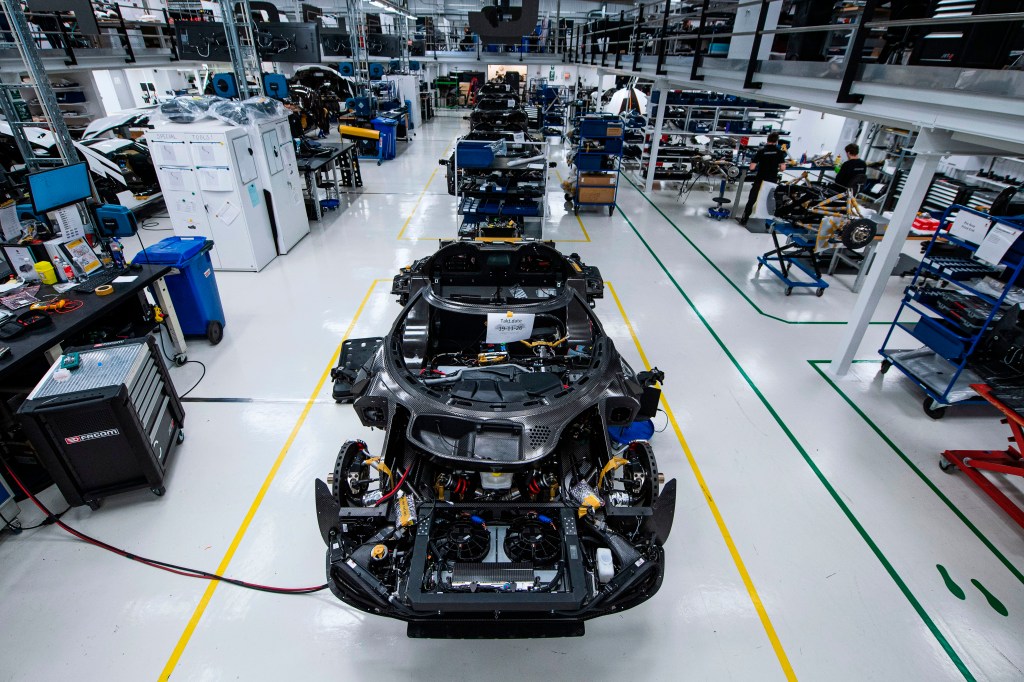

The Koenigsegg Jesko and its transmission are a showcase of the brand’s technological capabilities, but Koenigsegg’s progress moves far beyond just that. It’s a given that hypercars are made with carbon fiber. It’s light, strong, and light. Also, it’s very light. Once again, von Koenigsegg sought to improve on something that wasn’t broken. Here, the company has applied Formula1 technology to their cars. It’s an old trick, but boy do these Swedes make it work.

In addition to the Koenigsegg Jesko, all of the company’s cars use advanced pre-impregnated carbon fiber monocoque chassis (see image above) to help them be more rigid. Now, I could throw a bunch of math I’m too dumb to understand in here, but let’s just leave it at this: The brand’s carbon fiber technology helps make their cars lighter and more rigid than pretty much anything out there. Additionally, you can take the roof off, a classic weak point as far as rigidity goes. Pretty impressive, right?

The brand is pushing for sustainability too

The company has an eye on sustainability as well. Their factory is incredibly green in its production methods, and they’ve even created a new kind of catalytic converter to cut down on emissions.

The Koenigsegg Jesko is known for its power output, however, a catalytic converter restricts that. That’s why the brand created a totally new “Rocket” catalytic converter to increase power output while leaving emissions unchanged.

These forward-thinking methods have pushed Koenigsegg into the spotlight of both performance and sustainability, and if you ask me, they deserve to be there.