Global Semiconductor Sales Get a Boost as Sales Top Half a Trillion Dollars

As people get out and about, car buying and sales are seeing an uptick. The problem is that there aren’t enough cars to meet the needs of all the people looking to buy. Why are there not enough cars when there seemed to be an abundance of vehicles not too long ago? You can blame it on a little piece of technology you can hold in the palm of your hand. Here’s what’s happening with semiconductor production and sales around the world.

The chip shortage has worldwide ramifications

One piece of news capturing people’s attention across the globe is the worldwide chip shortage. These chips, otherwise known as semiconductors, are essential to the automotive industry, and a lack of them is a huge issue. This has been the primary reason car sales have been stagnant, availability has been short, and new and used vehicle prices have skyrocketed.

Many modern cars depend on these chips to run correctly. According to Wrench, semiconductors are essential for producing a chip. One chip can hold thousands of semiconductors, and these semiconductors are used to send information throughout the car. No semiconductors mean your vehicle is not going to run well.

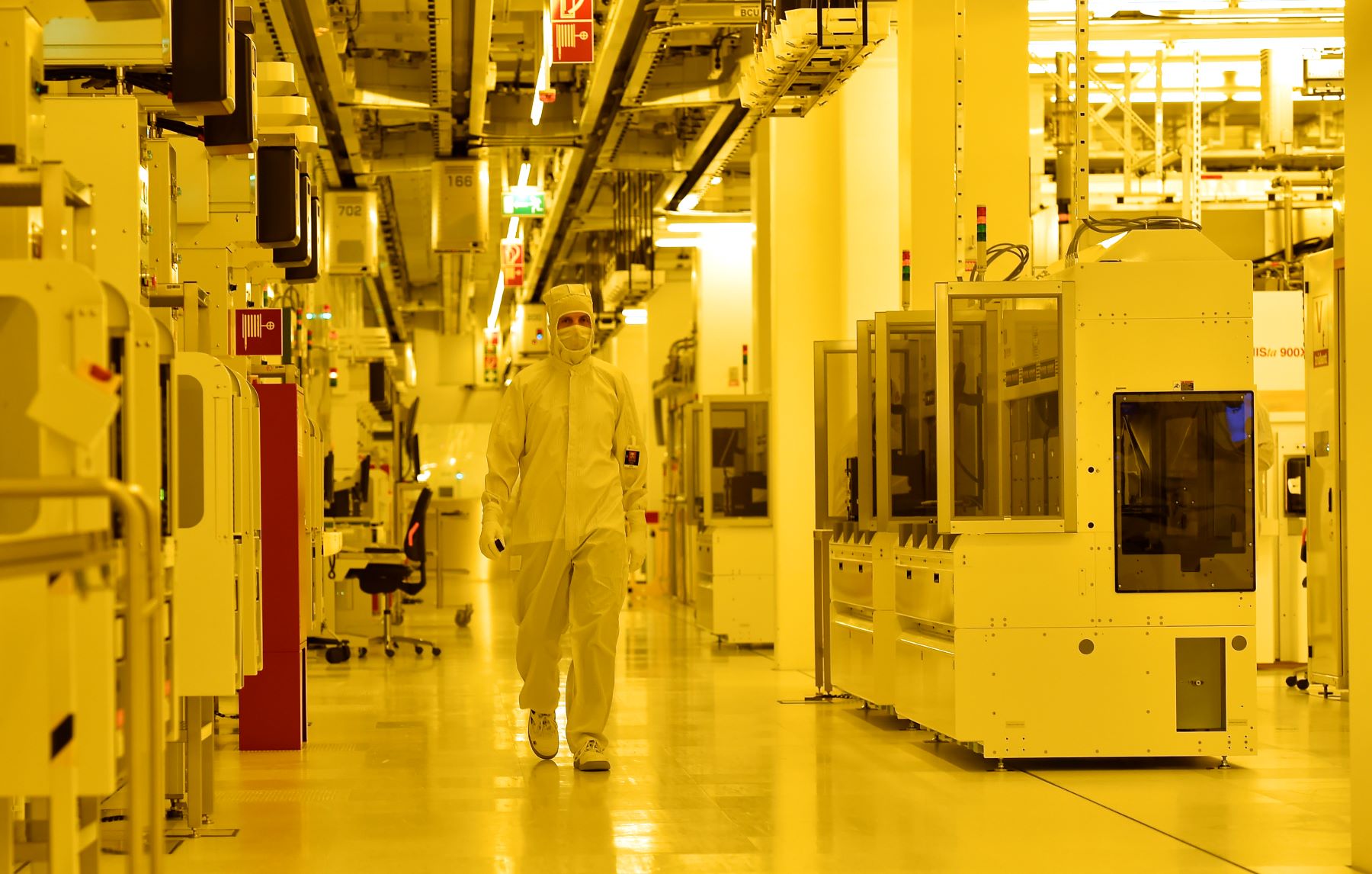

Semiconductors are very difficult and expensive to make and, for this reason, it would be challenging to find alternative chip suppliers to solve the current problem. The Semiconductor Industry Association (SIA) says they are “currently doing all [they] possibly can in the short-term, to increase utilization and meet increased demand both in the auto sector and more broadly for all customers.”

Many people worldwide are starting to drive more and are in the market for a new vehicle. You may have noticed that new cars are hard to find and if you do find a decent one, it is rather expensive. This leads to more people seeking out the same used vehicles as everyone else and coming up empty-handed.

Semiconductors see a boost in production and sales

According to CNBC, global semiconductor sales topped half a trillion dollars for the first time last year. The industry’s sales reached $555.9 billion in 2021, up 26.2% from the previous year. The industry produced a record 1.15 trillion semiconductors. This is thanks to companies ramping up the production of semiconductors to meet demand during the worldwide ship shortage.

John Neuffer, president and CEO of the Semiconductor Industry Association, said, “In 2021, amid the ongoing global chip shortage, semiconductor companies substantially ramped up production to unprecedented levels to address persistently high demand, resulting in record chip sales and units shipped.” He continues, “Demand for semiconductor production is projected to rise significantly in the years ahead, as chips become more heavily embedded in the essential technologies of now and the future.”

This increased production of semiconductors is receiving government aid to help get the industry healthy again. U.S. President Joe Biden set aside $50 billion for semiconductor manufacturing and research as part of the $2 trillion stimulus package. Also, the CHIPS for America Act is working its way through the legislative process to further aid in research and development. Additionally, the European Commission of the European Union announced the European Chips Act, which offers 15 billion euros to the effort.

Not just cars need the chips

The coronavirus (COVID-19) pandemic is one reason to blame for the shortage. The demand for semiconductors has gone up significantly over the last 10 years or so. Still, the global pandemic really shook up the industry, and it is taking time for it to recover. When the pandemic started, the demand for new cars went down, which caused the demand for semiconductors to go down. However, during this time, the need for semiconductors in consumer electronics increased, causing more semiconductors to be produced for electronics than for cars.

The demand for new cars has been going back up, but there aren’t enough semiconductors to meet the demand. This has forced major car manufacturers, such as Ford, General Motors, and Stellantis, to slow down their production of cars. Other Original Equipment Manufacturers (OEMs) have also shut down, affecting part suppliers who depend on them.

To add another layer to the chip shortage problem, cars are not the only products negatively affected by the shortage. Any piece of technology that uses semiconductors now has limits to its production. This is affecting anything from laptops and home appliances to medical devices.