Does Your Car Really Need Braided Stainless Steel Brake Lines?

Even if your car doesn’t rock Brembos, it needs solid and dependable brakes. That’s why they’re not only important maintenance items but also potential modification spots. For some, that means larger calipers; for others, slotted and/or drilled rotors. However, arguably even more common is giving cars braided stainless steel brake lines. But is this a modification worth investing in, or are the potential benefits overblown?

What do your car’s brake lines do?

Regardless of what brake brand or pad material your car uses, modern brake systems work on the same hydraulic principles. And that includes the physical brakes on cars with regenerative braking.

At the heart of a car’s braking system is the brake master cylinder, which is linked to the calipers via multiple brake lines. This cylinder, along with the lines, is filled with brake fluid. Pressing on the brake pedal pressurizes the fluid in the cylinder, which sends that pressure down the lines. And it’s this pressure that makes the calipers clamp their pads down on the rotors to slow you down, Autoweek explains.

In most cars, the brake lines are made of rubber with metal fittings on the end. Technically, those metal parts are the ‘lines’ or ‘pipes,’ CarThrottle explains, while the rubber parts are the ‘hoses.’ But most just call the whole assembly a ‘brake line.’

What makes braided stainless steel brake lines supposedly better than regular ones?

Regardless of the terminology, like other rubber parts, brake lines degrade over time. Sometimes that means they crack and leak fluid. But worse, especially for racers, is that they swell. If your brake lines swell, that means they’re not transmitting 100% of the available pressure to the calipers. And if that happens, you’ve lost braking performance and potentially feedback. Both are anathema to a racer.

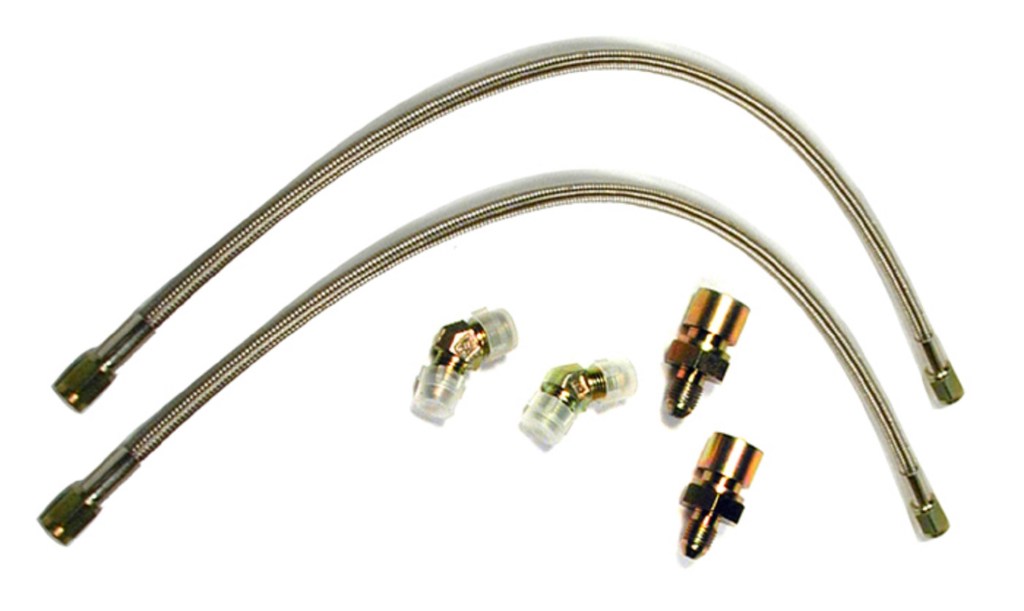

That’s where braided stainless steel brake lines come in. Instead of a bare rubber hose, these are made of braided stainless-steel fibers, MotorTrend explains. These fibers are wrapped around a nylon or Teflon core that the brake fluid flows through. And this construction gives stainless steel brake lines several advantages over bare rubber ones.

For one, stainless steel doesn’t degrade like rubber. It’s also more resistant to nicks from things like road debris and rocks. Plus, braided steel lines don’t have to be replaced nearly as often as rubber brake lines, Bennetts notes. And, most importantly, it doesn’t swell under pressure, even in the heat and intensity of a racetrack session. That way, your brake pedal stays firm and responsive. It might not improve your braking distances significantly, but it will improve your confidence in your brakes. And confidence is vital on the track.

How much do they cost?

Braided stainless steel brake lines usually come as part of a pre-assembled kit, though there are DIY ones available. And they’re often included in high-end ‘big brake’ kits.

If you’re buying them as a stand-alone mod, prices vary based on your car’s make and model. But generally speaking, a set of braided stainless-steel brake lines from a brand like Wilwood costs roughly $100. Though that doesn’t include an installation fee if you’re going to a mechanic.

Do stainless steel brakes lines make enough of a difference?

Considering the relatively low cost, braided stainless steel brake lines seem like a win-win. And you can save some cash by doing the installation work yourself. Just remember to bleed the brakes properly and top up the brake fluid.

However, there are a few more factors to consider. Firstly, stainless steel is more abrasive than rubber, and can damage surrounding components, CarThrottle notes. Secondly, braided lines hide internal damage more than plain rubber ones. Also, cheap lines sometimes use nylon cores instead of Teflon ones—and nylon can melt “in extreme circumstances,” Bennetts warns.

Plus, as the video above explains, stainless steel brake lines are more rigid than rubber ones. That makes them more difficult to install. And if you install them improperly, you have a brake fluid leak on your hands. That rigidity also means they can pop out of their fittings under impacts, whereas rubber brake lines would flex away without issue.

But arguably most importantly, braided stainless steel brake lines don’t make a significant difference on the street. Yes, they’re more resilient and swelling-resistant, but that really only matters on a racetrack. Around town, the supposed improvements are negligible. It’s just like with carbon-ceramic brakes in that they’re designed around high-speed, high-intensity driving. Also, if your goal is a firmer, more responsive brake pedal, that’s often achievable just by replacing your old brake lines with fresh ones.

In short, installing aftermarket braided stainless steel brake lines is critical if you’re building a race car. But for road cars, there are other modifications better worth your time and money.

Follow more updates from MotorBiscuit on our Facebook page.